What is the difference between Industry 3.0 and Industry 4.0?

In terms of the words themselves, Industry 4.0 refers to the fourth industrial revolution. The term was coined in 2011 to represent the role that cyber-physical systems (CPS), cloud computing, and IIoT (industrial internet of things) will have on manufacturing processes. This technology’s impacts include:

- Interoperability

- Decentralization of information

- Real-time data collection

- Heightened flexibility

As such, the difference between Industry 3.0 and Industry 4.0 is the presence of new interconnected technologies in plant operations.

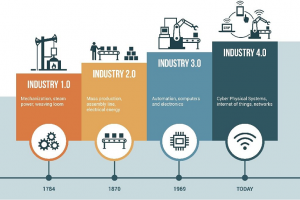

A brief history of industry

To explore this further, let’s look at historicalindustrial revolutions:

- 1st industrial revolution – Steam and water power are used to mechanize production

- 2nd industrial revolution – Electricity allows for mass production with assembly lines

- 3rd industrial revolution – IT and computer technology are used to automate processes

- 4th industrial revolution (Industry 4.0) – Enhancing automation and connectivity with CPS

We’ve basically followed a sequence of increased automation, and the final development (which is still underway) takes that automation to a whole new level by making use of big data.

What is the difference between Industry 3.0 and Industry 4.0?

In Industry 3.0, we automate processes using logic processors and information technology. These processes often operate largely without human interference, but there is still a human aspect behind it. Where Industry 4.0 comes in is with the availability and use of vast quantities of data on the production floor.

For an example of the old way (Industry 3.0), take a CNC machine: while largely automated, it still needs input from a human controller. The process is automated based on human input, not by data. Under Industry 4.0, that same CNC machine would not only be able to follow set programming parameters, but also use data to streamline production processes.

What will Industry 4.0 look like?

In terms of maintenance, Industry 4.0 means lots of data can be collected through sensors and used to make decisions about repairs and upkeep. Predictive maintenance systems are even beginning to implement machine learning to determine when asset failure may be imminent and prescribe preventive measures.

Now, this doesn’t mean we weren’t using data before—we’ve been gathering data for decades. The difference is simply the sheer volume of data available and the new methods we have for handling it all.

IIoT with CPS and cloud-based processes allow us to gather and interpret data in ways that weren’t possible before, and the impact of those technologies is being felt in every aspect of manufacturing, from production to maintenance to marketing, and even then on to the final products we create.

To be a bit trite, Industry 4.0 is the way of the future.

Want to keep reading?

Industry 4.0 Explained | What Is Industry 4.0?

What Is IIoT (Industrial Internet of Things)?

Industrial IoT Sensors: What Are They and Which Businesses Use Them

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)