UpKeep CMMS for Food & Beverage: The #1 Software for Food and Beverage Manufacturers

Maintain regulatory compliance, keep production moving, and reduce asset and maintenance costs in your food and beverage manufacturing facilities.

No credit card required.

UpKeep’s CMMS for Food & Beverage Provides Amazing Results

90%

Reduction in technician time spent filing work orders and locating asset information

315%

Return on Investment

$638K

Savings from avoided production downtime

Benefits of Utilizing CMMS Software for Food and Beverage Manufacturing

If you’re in the food and beverage manufacturing industry, using a CMMS from UpKeep will help your bottom line. Your initial investment in the software will reap benefits to save time and money in the long run.

These include:

Streamlined maintenance processes

Reduced downtime

Extended lifespans of critical food and beverage manufacturing equipment

Quality and safety regulation compliance

Enhanced inventory management

Valuable data insights

And more

In the highly competitive food and beverage manufacturing industry, CMMS software becomes a strategic tool for maintaining the highest levels of product quality, safety, and profitability. This makes it indispensable for any manufacturing operation.

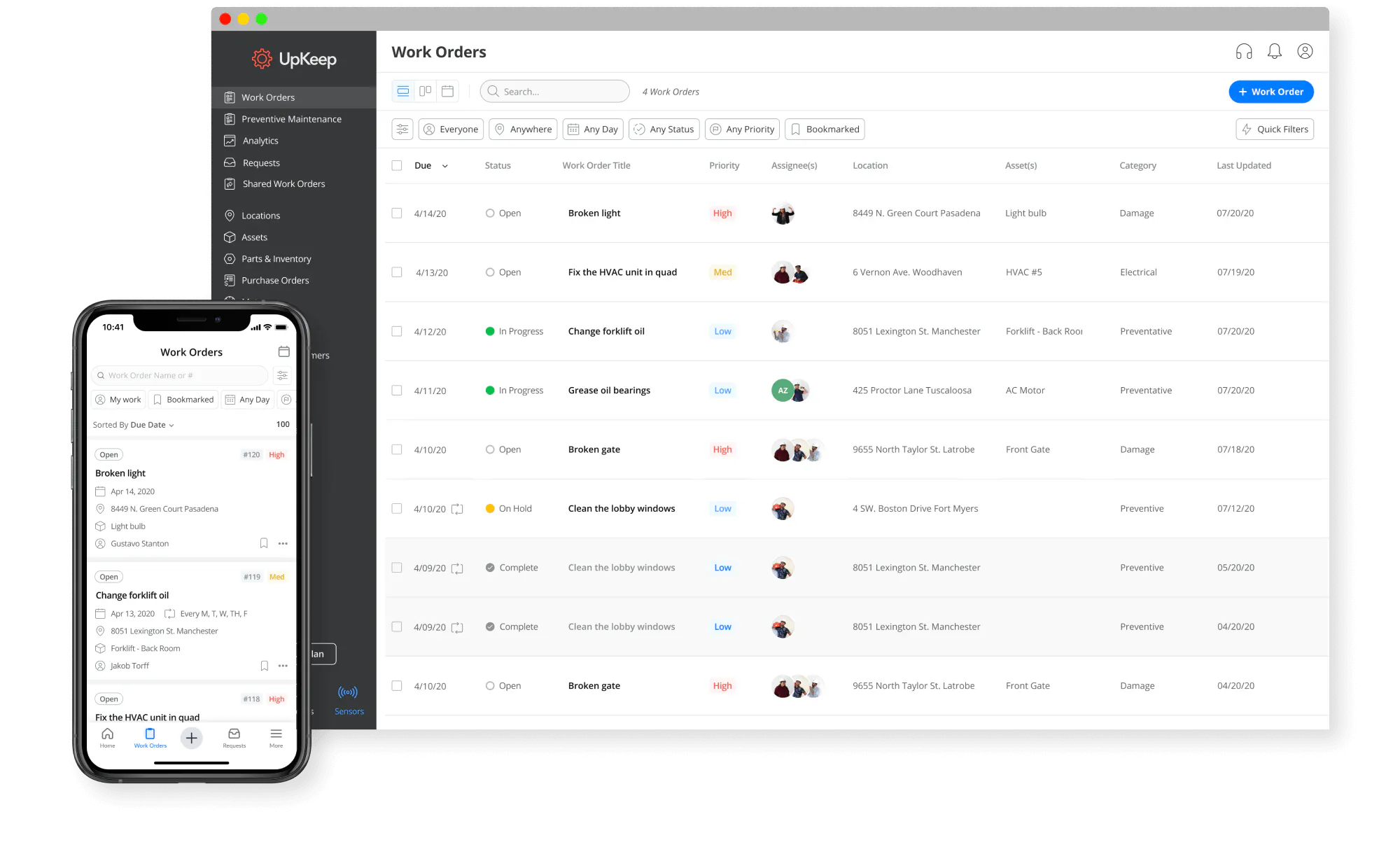

Maximize Food and Beverage Manufacturing Maintenance Operations: Powerful Tools To Get the Job Done No Matter Where You Work

Whether you’re at the office or in the field, ensure best-in-class food and beverage manufacturing maintenance operations.

UpKeep ensures compliance in the food and beverage industry by providing historical documentation, easy-to-find manuals, compliance templates, preventive maintenance tasks, configurable analytics, and reporting.

Key Features of CMMS for Food & Beverage

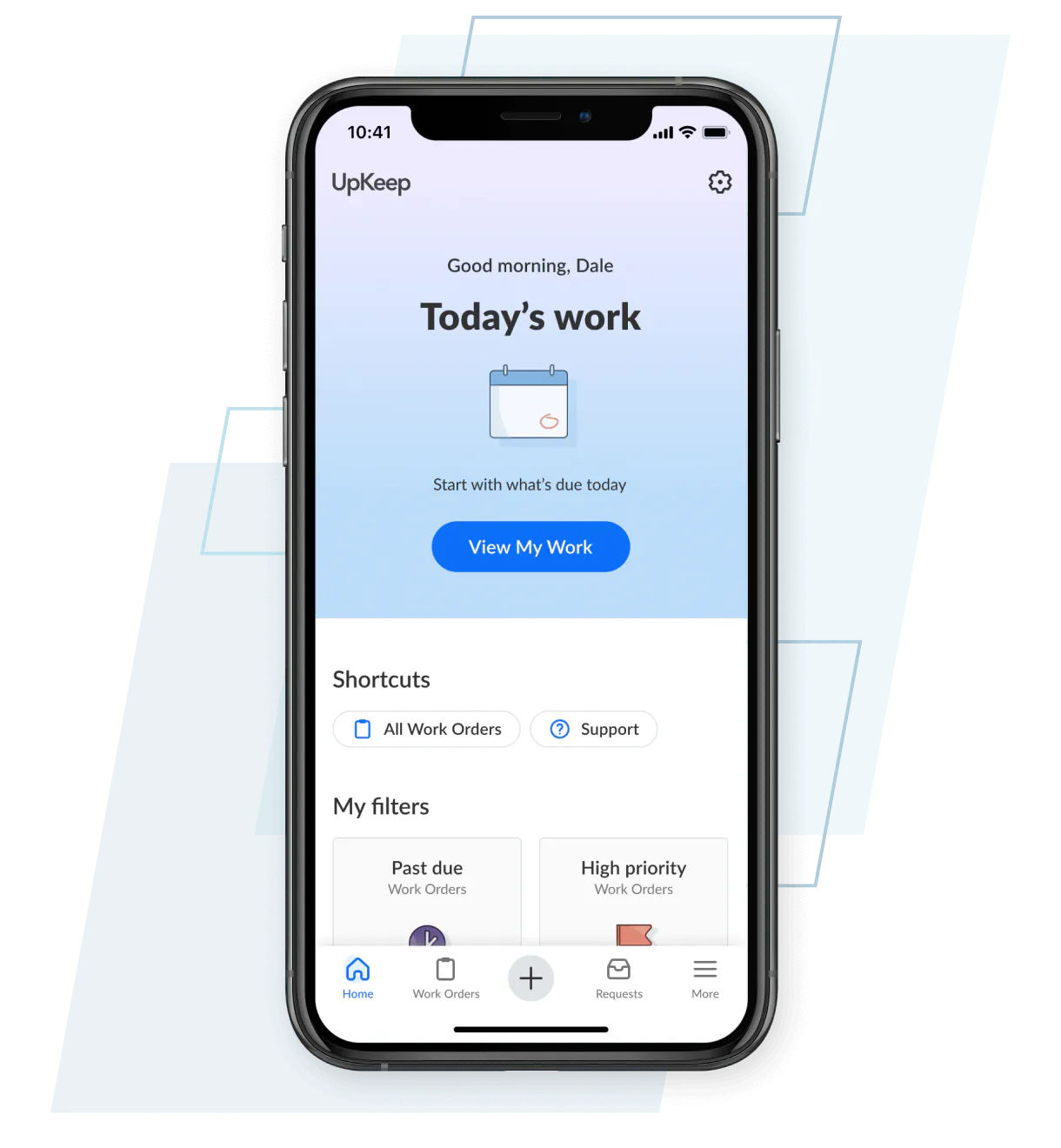

A Powerful Mobile Tool That Anyone Can Pick Up Quickly

Food and beverage manufacturing teams that use a mobile CMMS experience up to a 652% return on investment through better communication and consistency. Keep your maintenance management consistent and flawless by allowing your team easy access to beneficial information and communication platforms.

Even the best software platforms are only advantageous if your crew and technicians can figure them out. UpKeep allows even your least tech-savvy team member to easily use its software by providing a user-friendly interface.

Food & Beverage Maintenance Management and Work Order Software

UpKeep is consistently rated the best inventory management software in value for money, ease of use, functionality, and customer support. There’s a reason UpKeep has more 5-star reviews than any other CMMS vendor.

UpKeep allows you to:

Reduce your equipment and asset downtime by up to 26%.

Extend your asset and equipment lifetime by up to 11%.

Achieve up to 652% ROI by integrating UpKeep into your workflow.

Improve overall facility condition.

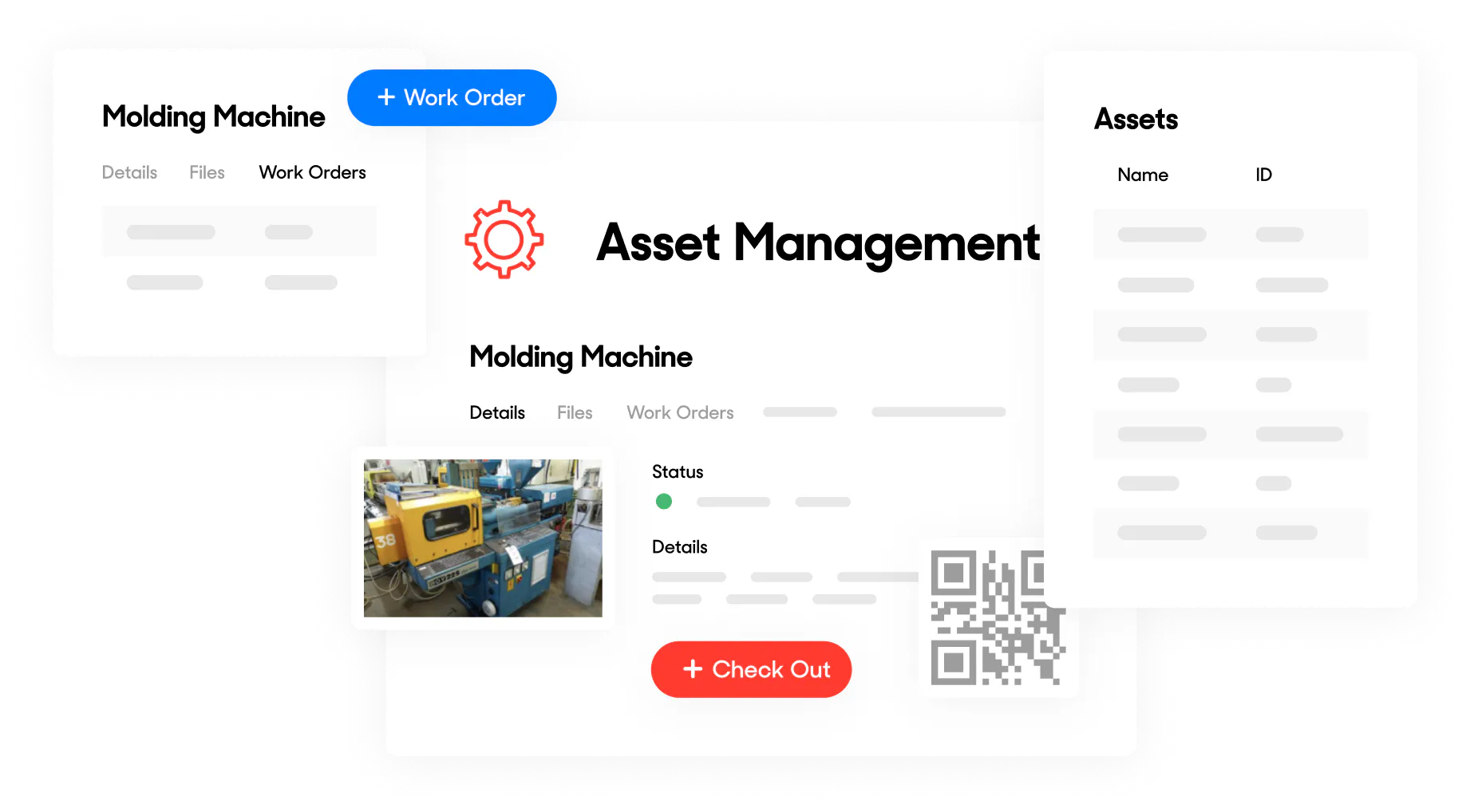

Easily Manage Your Assets from Any Mobile Device

Allow technicians to easily access preventive maintenance checklists and manuals from anywhere at any time.

All necessary asset information is secure and can only be accessed by authorized individuals.

Technicians can reference the records of previous repairs to make knowledgeable decisions.

Use UpKeep Analytics to track equipment downtime for cost and energy efficiency.

FAQs About Food and Beverage Manufacturing CMMS

Food and beverage manufacturing software can encompass a broad range of technology required for the organization to work effectively and efficiently.

Many food and beverage manufacturers today use enterprise resource planning, accounting packages, inventory management tools, computerized maintenance management software, and many others that may operate as stand-alone solutions or be integrated to work together.

For example, software may be able to track raw material orders, inventory levels, and freshness dates on the front-end of food and beverage production. Other technology can be used to manage the accounting side from supplier payments to invoicing customers. A maintenance platform can incorporate preventive maintenance schedules as well as manage data from equipment sensors in a predictive maintenance program.

Ideally, all these technologies share data and communicate with one another to keep the organization running smoothly and efficiently.

Asset Operations Management (AOM) threads together an organization’s technician services, passive and active data, and unique operational blueprint to make it easier and faster for every employee to get what they need to do their jobs successfully.

AOM can help food and beverage manufacturers manage multi-location, day-to-day maintenance life cycles; optimize asset utilization; and gain insights into real-time performance data. Maintenance, reliability, and operations teams now have one easy-to-use tool to drive efficiency and effectiveness across the organization.

When all these previously siloed departments can work together to focus on the optimal performance of critical assets, food and beverage manufacturers can boost their overall efficiency, improve on key performance indicators, and generate long-term, sustainable revenue and success.

UpKeep’s CMMS schedules and tracks maintenance tasks, inspections, and audits to ensure all equipment and processes meet regulatory standards, which will help lead to the highest levels of food and beverage safety and quality.

Our CMMS will automate the scheduling of routine maintenance tasks, send reminders to the team, and track all maintenance history. This helps ensure that all your food and beverage manufacturing equipment is properly maintained, reducing breakdowns and saving you time and money.

The implementation process of a new CMMS involves data migration, software configuration, user training, and ongoing support. At UpKeep, we don’t believe in a one-size-fits-all solution — so we can tailor our software to the specific needs of your facility. Request a free product tour to see how we will help your organization maximize profits and efficiency.

Yes, UpKeep can easily be integrated with enterprise resource planning software and other systems to improve your overall operational efficiency levels.

Food and Beverage Manufacturing CMMS Buyer’s Guide

CMMS Buyer's Guide

There are many factors to take into account when choosing a CMMS, especially in the food and beverage manufacturing industry. The goal of this Buyer’s Guide is to help food and beverage manufacturers navigate the process of selecting a CMMS for their organization.

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability