What Is a CMMS?

This article dives deep into the basics of computerized maintenance management systems (CMMS). You'll learn about what a CMMS is, what it does, and how its benefits can best be harnessed. Already in the know? Schedule a demo to see UpKeep's preventive maintenance solution first hand.

The CMMS Buyer's Guide

The Essential CMMS Implementation Guide

What Should You Look for in a CMMS?

What Is CMMS Software & What Does it do?

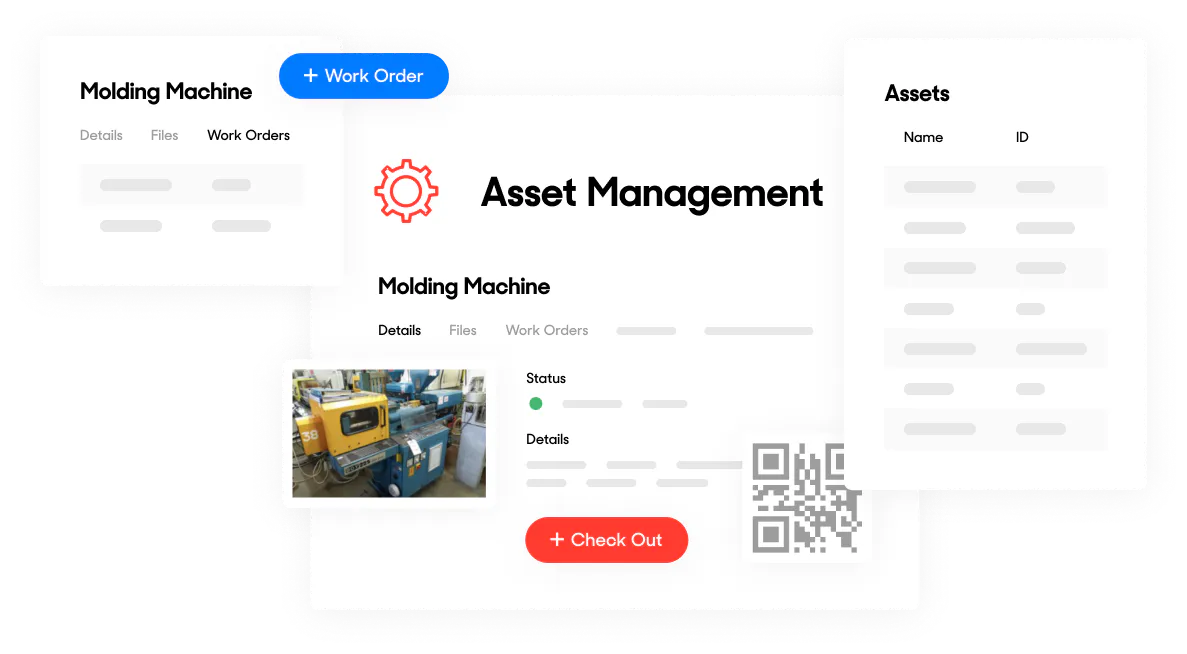

A computerized maintenance management system (CMMS), also referred to as maintenance management software or asset management software, is software that stores data about maintenance operations, such as maintenance performed on equipment, machinery, and other assets. CMMS software improves asset management by eliminating the need for manual spreadsheets and consolidating all maintenance team activities in one place.

With a CMMS system, teams can easily record and organize asset data, plan preventive maintenance tasks, create work orders, and generate reports. Modern systems even operate on multiple platforms, from desktop PCs to handheld tablets and smartphones, making them a powerful way to streamline maintenance processes.

History of CMMS

The first CMMS software appeared around 1965 and was used by large manufacturers that owned IBM mainframe computers (the beastly kinds that are not used anymore). Teams would log data on punchcards that were fed to the computer. Years later, they would log data on paper that was given to data entry specialists. Only in the 1980s when computers became more usable did technicians log data themselves directly into the asset management software.

Usability is now less of an issue in the 21st century with personal computers. And a CMMS is not reserved for large manufacturers that have high maintenance budgets. Today, the solution is used by companies that have internet in their facility and even the smallest maintenance budgets. This is because solutions are web-based and relatively affordable.

Accessibility and affordability aside, today, a CMMS is judged mainly on its features and ease of use for managers to make data-driven decisions about maintenance operations. Usability is still an important factor because, as more features are added, solutions can become increasingly complex which decreases any chance for successful implementation.

A CMMS helps teams organize maintenance tasks and track maintenance activity, while allowing managers to streamline processes. And some are free to use! However, many companies are still using pen and paper, spreadsheets, or don't even have maintenance operations, according to an UpKeep survey.

With CMMS products easier than ever to use and widely available to teams with different budgets, it’s at least worth testing one!

How a CMMS Works

At a high level, computerized maintenance management software is a data-driven solution, and the work order feeds that data. When an order is closed, the data is processed by the system. Work orders contain key asset maintenance data including parts and costs, wrench time, asset repaired, and time to complete. This data is then processed into reports used by maintenance managers and other departmental heads to make data-driven decisions.

Any time a work request is submitted, maintenance teams use a CMMS to create an order. Additionally, recurring orders may be created to handle preventive maintenance and inspections. Some systems can even automatically generate orders based on data from sensors. After the order is completed by a technician, it’s closed out and the data is entered into the system, making it available for reports and planning.

A mobile CMMS can streamline this entire maintenance process by allowing technicians to access and update work order information on site, saving valuable labor hours by keeping travel times to a minimum. Assuming data is entered into the system consistently, processes like maintenance planning, scheduling, root cause analysis, and so forth are expedited by making information easily accessible.

Summary

A work order is created and assigned to a technician and asset.

A technician updates the work order with new data (parts used, costs, time spent, meter readings, etc.) as they complete the work order.

The CMMS software processes the data and updates the asset record.

As the data is surfaced, management runs reports that reveal labor-intensive assets, technician productivity, and costs.

4 Key CMMS Features

Work Order Management

Work Requests

Enterprise Asset Management

Mobile App

What Industries Use a CMMS?

Any industry that has any degree of maintenance operations needs can benefit from using CMMS software. The features they use may change depending on the scale of their operations and types of assets used, but the fundamental functions of generating and managing work orders are integral to most organizations.

Some of the industries that benefit from implementing a one include:

Each of these industries has assets that need regular maintenance, whether those include large industrial machines, mobile equipment, buildings, or land. By managing their maintenance tasks through a CMMS, their MRO processes become more efficient, taking less time and money to perform effectively. As a result, each of these industries can reduce overhead, even if onlyy used for work order management.

Types of CMMS Software

A CMMS can be divided into two general types: on-premise and cloud-based. The option you choose will have a significant impact on the way you use the software.

On-Premise

An on-premise CMMS is an in-house software system that handles maintenance and inventory management. You often pay upfront for the installation of the system and are responsible for setting up firewalls and IT infrastructure. These systems were used before high-speed Internet and software-as-a-service (SaaS) products existed. Today, cloud-based products are used.

Cloud-Based

Unlike an on-premise solution, a cloud-based CMMS is managed by the provider, so all you need to do is focus on using the product. With a software that's hosted on infrastructure managed by the provider, updates happen automatically. You get new features without having to install a new version of the software. With on-premise, you must make updates to the system yourself as they become available.

Another benefit of cloud-based is the ability to enter maintenance data from anywhere. It lets technicians use a mobile application to view and update a work order from the repair site or anywhere else there is an internet connection. The mobile application syncs with the main server where all maintenance data is hosted. This way, technicians don’t have to re-enter data from a desktop computer.

Want to learn more?

What Is Preventive Maintenance? | Overview, Benefits & Examples

What Is a Work Order? | The Beginner's Guide from UpKeep

The inside look

Frequently Asked Questions

Maintenance shouldn’t mean guesswork and paperwork. UpKeep makes is simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

Before investing in a CMMS, it’s important to define your goals and have a good understanding of your maintenance needs. You’ll also need to set up the infrastructure including a leader and budget. Once those things are in place, review a few options, select a solution to try, and conduct a trial run to see how the solution works for your organization before making a big commitment.

Many CMMS solutions are available today. Given the speed of the market, it’s important to look at cloud-based solutions for asset maintenance. On-premise solutions aren't user-friendly, are being phased out, and simply do not provide you with the flexibility and features that cloud-based, mobile solutions now offer.

Since providing a CMMS solution is the core business for a CMMS provider, security issues tend to be a high priority. Protecting a customer’s information and data must be paramount for a CMMS business to continue to thrive and grow. The advantage, however, is that a CMMS provider can embrace best-in-class security measures and pass along those safeguards to all their customers.

UpKeep’s CMMS supports several types of maintenance. Reactive or emergency maintenance work orders can be entered into the system and prioritized with the day’s tasks. UpKeep’s CMMS can also schedule maintenance tasks ahead of time, so that when weekly, monthly, or quarterly inspections tasks arise, they automatically generate work orders on the appropriate day. Finally, UpKeep can integrate with technology such as sensors, which can facilitate predictive maintenance tasks. For example, when a vibration sensor falls out of a prescribed range, a work order can be automatically generated.

It’s understandable that management wants to understand the asset management ROI of a CMMS. Depending on your company and what areas you're trying to improve, there are many measurements and KPIs that you can employ. Here are a few major considerations:

- According to the U.S. Department of Energy, a company can save 12 to 18 percent of the costs associated with repair and emergency asset maintenance when it switches to predictive maintenance.

- A report from Jones Lang LaSalle states that a company can generate an ROI of 545 percent over 20 years from switching to preventive maintenance over reactive maintenance.

- Uptime levels from plants typically employing reactive maintenance achieve an uptime of 83.5 percent, while those that focus on planning, scheduling, and predictive maintenance can boost that number to 98 percent, according to Reliability Incident Management.

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability