UpKeep AI Suggestion

Search Results

What's an MOC (management of change) and what do I use it for?

Want to keep reading?

CMRP Certification: Everything You Need to Know

When it comes to passing the CMRP exam, there’s a lot of information out there. So we’ve put everything you need to know in one place.

Management of Change

The details outlined in an MOC help a business ensure new or increased hazards are identified and mitigated with any organizational change.

Tips on Safety Maintenance: Keeping Your Crew and Machinery Safe

Maintenance work differs greatly from day-to-day operations—every task is unique, and there is typically little room for automation.

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)

Management of change (MOC) is a policy companies use to manage any health, safety or environmental risks that arise when facilities, employees, or operations are updated, added, or otherwise modified. The details outlined in an MOC help a business ensure that new or increased hazards are identified and mitigated with any organizational change.

Why are MOCs needed?

According to Inspectioneering, an effective MOC should review any facility, process, or personnel change before implementation. This procedure is required by the Occupational Safety and Health Administration (OSHA) when any change, whether temporary or permanent, could affect the safety of a facility.

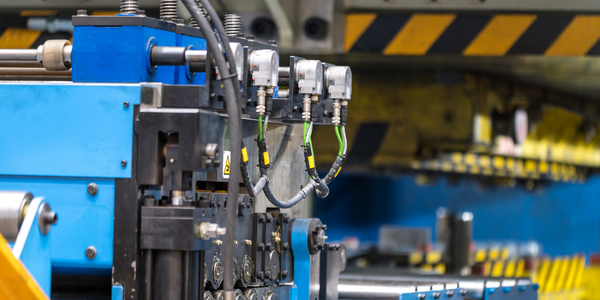

Examples of company changes that would require an MOC evaluation include increasing the number of employees completing a process, changing the chemicals used in a production line, or upgrading a piece of equipment. These changes, left unchecked, could increase employee injury, damaged equipment, or environmental pollution.

What are the benefits of MOC?

When an organization implements an MOC, it derives many benefits. First and foremost, an MOC helps a business minimize unexpected adverse situations related to security, reliability, stability, or integrity that might occur with a process or equipment change.

Since change nearly always affects production and efficiency, at least temporarily, having a clear MOC can help a team reduce this cost to a minimum by ensuring that the change has been completely checked, inspected, and tested before implementation. It also helps set expectations and establishes required checks and balances between technical and management staff.

MOC Best Practices

Companies that embrace the best practices of MOC will follow the following process and procedures.

First, start by pulling together all safety data that are relevant to whatever change is occurring. Add new information related to the change into existing procedures, including changes to accident investigation or audit compliance. Be sure to gather input from key employees during this process and incorporate their ideas and suggestions.

It’s critical to train and educate all employees on the MOC procedures that result. Clear, step-by-step instructions will be needed in order to ensure effective execution in the case of an accident or emergency. Update all written material so that the next MOC can be completed quickly and efficiently.