What Is a CMMS?

This article dives deep into the basics of computerized maintenance management systems (CMMS). You'll learn about what a CMMS is, what it does, and how its benefits can best be harnessed. Already in the know? Schedule a demo to see UpKeep's preventive maintenance solution first hand.

The CMMS Buyer's Guide

Guía de implementación esencial de CMMS

What Should You Look for in a CMMS?

Want to learn more?

What Is Preventive Maintenance? | Overview, Benefits & Examples

What Is a Work Order? | The Beginner's Guide from UpKeep

The inside look

Frequently Asked Questions

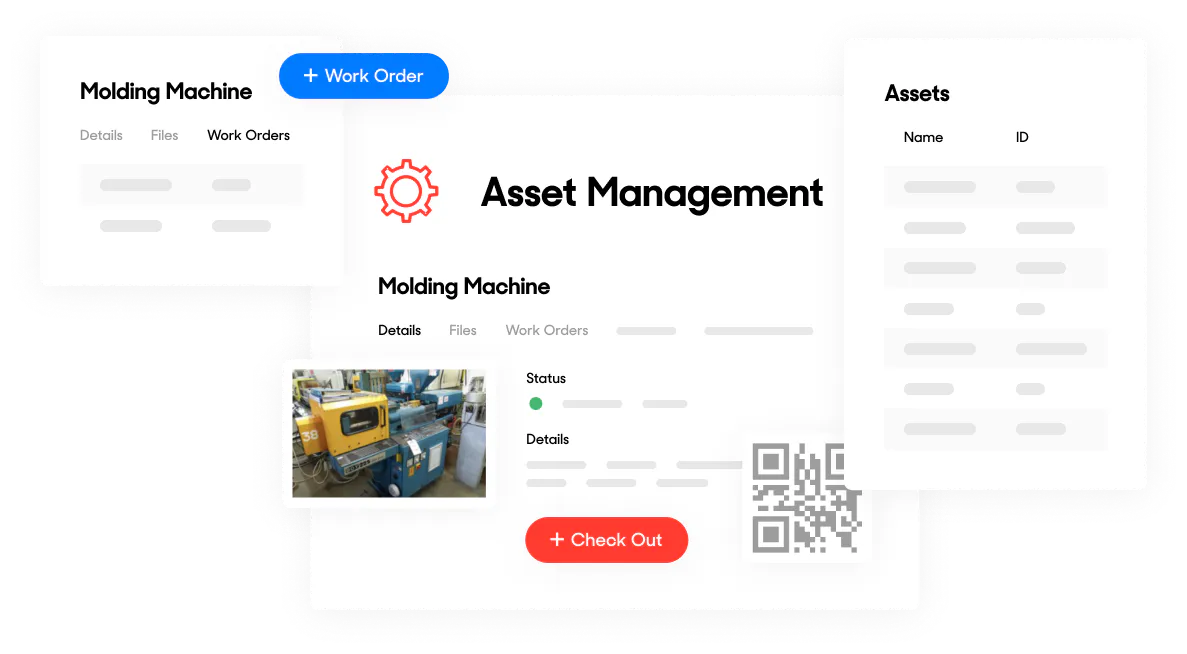

Maintenance shouldn’t mean guesswork and paperwork. UpKeep makes is simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

Before investing in a CMMS, it’s important to define your goals and have a good understanding of your maintenance needs. You’ll also need to set up the infrastructure including a leader and budget. Once those things are in place, review a few options, select a solution to try, and conduct a trial run to see how the solution works for your organization before making a big commitment.

Many CMMS solutions are available today. Given the speed of the market, it’s important to look at cloud-based solutions for asset maintenance. On-premise solutions aren't user-friendly, are being phased out, and simply do not provide you with the flexibility and features that cloud-based, mobile solutions now offer.

Since providing a CMMS solution is the core business for a CMMS provider, security issues tend to be a high priority. Protecting a customer’s information and data must be paramount for a CMMS business to continue to thrive and grow. The advantage, however, is that a CMMS provider can embrace best-in-class security measures and pass along those safeguards to all their customers.

UpKeep’s CMMS supports several types of maintenance. Reactive or emergency maintenance work orders can be entered into the system and prioritized with the day’s tasks. UpKeep’s CMMS can also schedule maintenance tasks ahead of time, so that when weekly, monthly, or quarterly inspections tasks arise, they automatically generate work orders on the appropriate day. Finally, UpKeep can integrate with technology such as sensors, which can facilitate predictive maintenance tasks. For example, when a vibration sensor falls out of a prescribed range, a work order can be automatically generated.

It’s understandable that management wants to understand the asset management ROI of a CMMS. Depending on your company and what areas you're trying to improve, there are many measurements and KPIs that you can employ. Here are a few major considerations:

- According to the U.S. Department of Energy, a company can save 12 to 18 percent of the costs associated with repair and emergency asset maintenance when it switches to predictive maintenance.

- A report from Jones Lang LaSalle states that a company can generate an ROI of 545 percent over 20 years from switching to preventive maintenance over reactive maintenance.

- Uptime levels from plants typically employing reactive maintenance achieve an uptime of 83.5 percent, while those that focus on planning, scheduling, and predictive maintenance can boost that number to 98 percent, according to Reliability Incident Management.

Get Started